The SUSTAINABILITY District

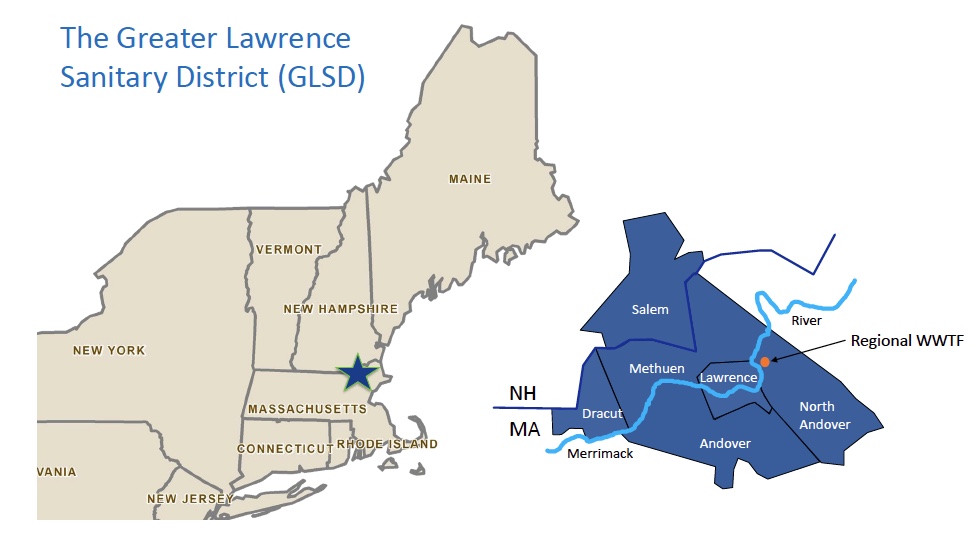

Greater Lawrence Sanitary District (GLSD)

August 2018

A 4th, new anaerobic digester at GLSD will recycle food waste & generate renewable energy - enough to power the facility!

How does a wastewater treatment facility

lead in SUSTAINABILITY?

Co-digest.

And recycle.

GLSD in North Andover, Massachusetts has leaped past many other WRRFs in the region, setting a new standard for sustainability.

Here’s the story….

It begins with food scraps… …and toilets.

And where does it end? Maybe never?

(That’s the goal, right?)

dried, pelletized biosolids fertilizer

It’s a cycle,

producing green electricity…

…and biosolids fertilizer used on

Massachusetts farms & landscapes.

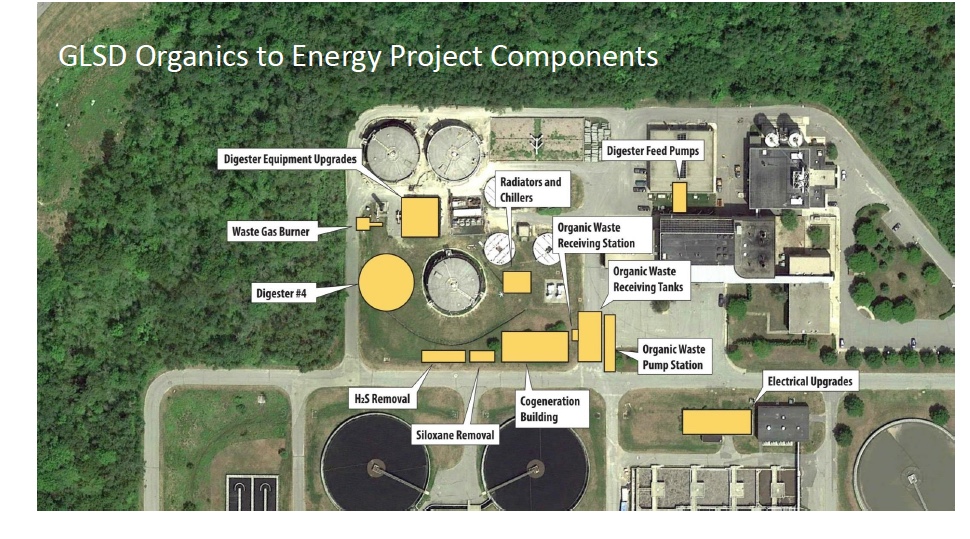

And there are a whole bunch of steps in between:

(see photos below)

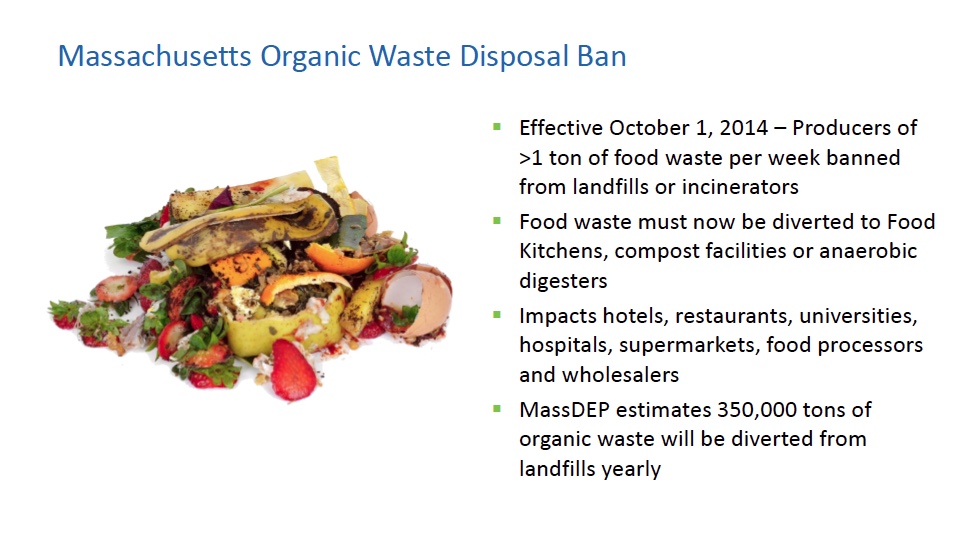

Food scraps, in slurried form, are delivered by trucks to the water resource recovery facility (WRRF) at GLSD.

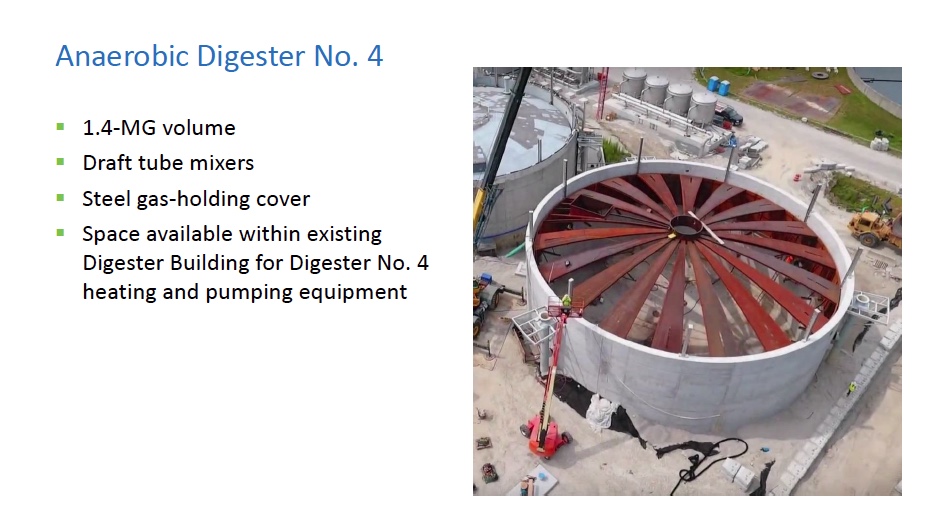

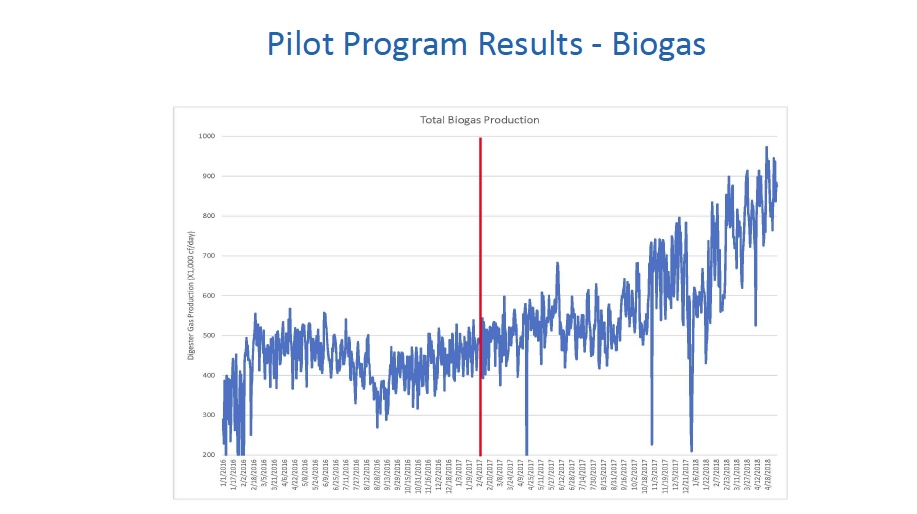

Huge tanks - anaerobic digesters - hold the food slurry and wastewater solids (the dead microbes and other solids taken out at the WRRF when cleaning wastewater), breaking them down naturally to create biogas - renewable methane. (More about anaerobic digestion…)

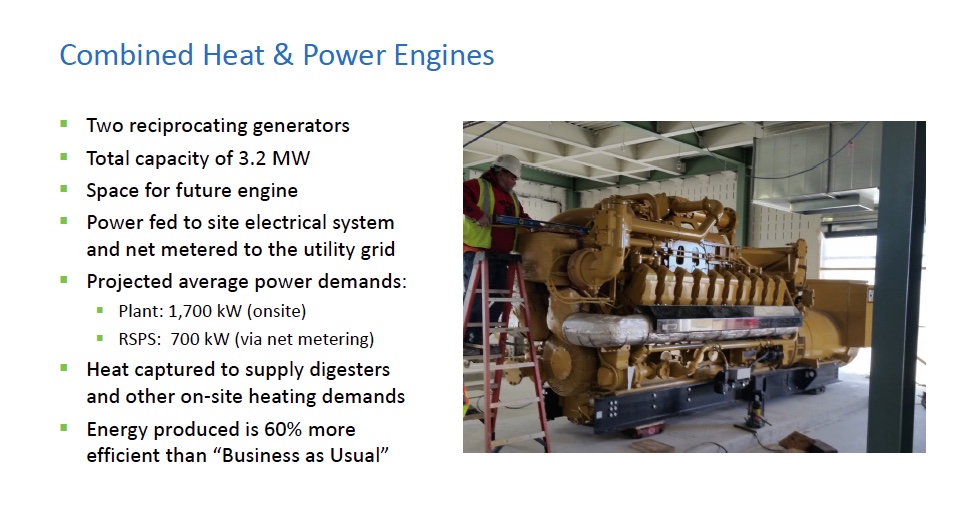

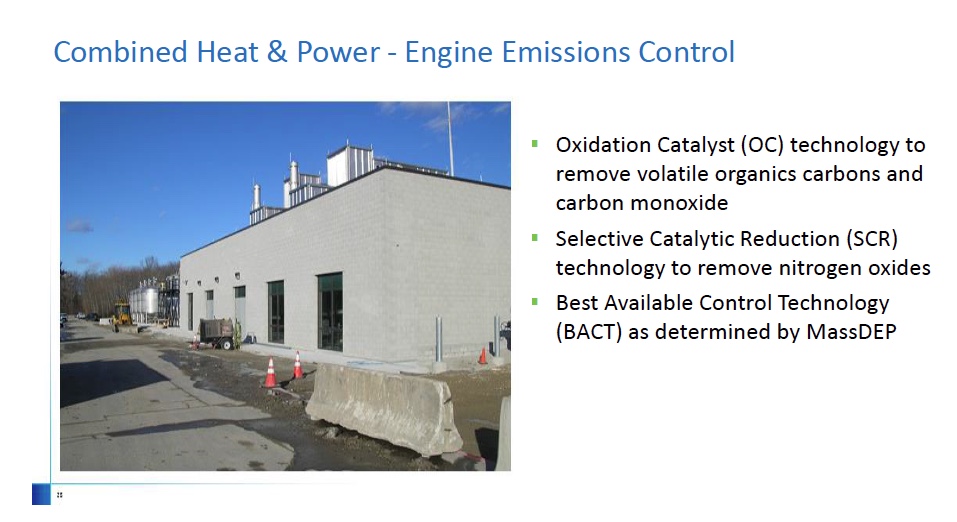

Biogas is burned in engine generators for electricity that powers wastewater treatment, and…

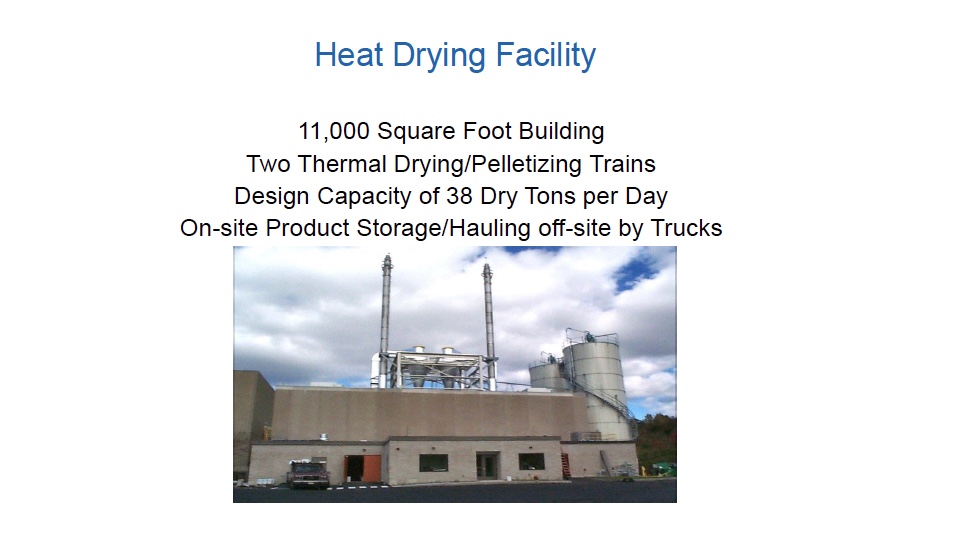

…biogas is burned in rotating dryers that dry the solids.

Screens size the dry solids into convenient fertilizer pellets…

…that are stored in silos…

…and trucked to farms to grow crops…

…some of which become food scraps….

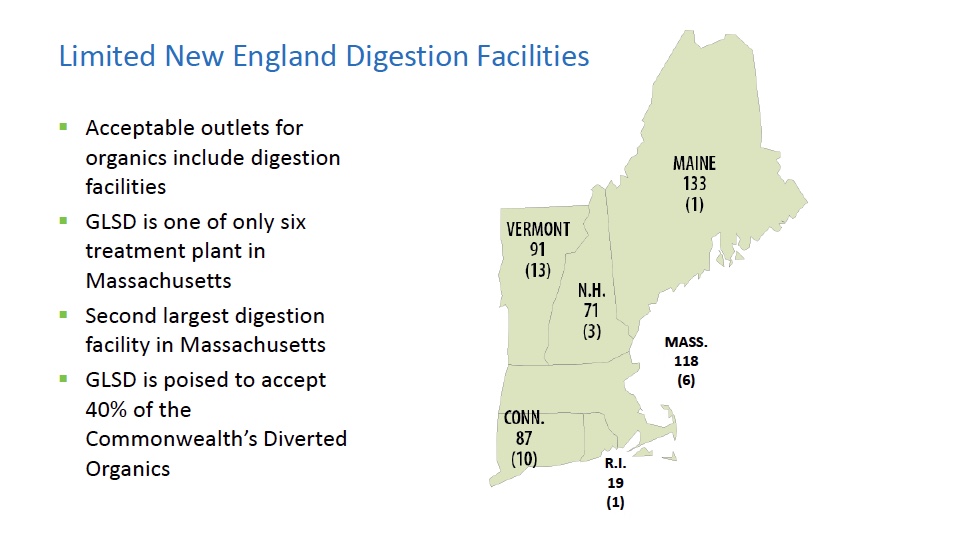

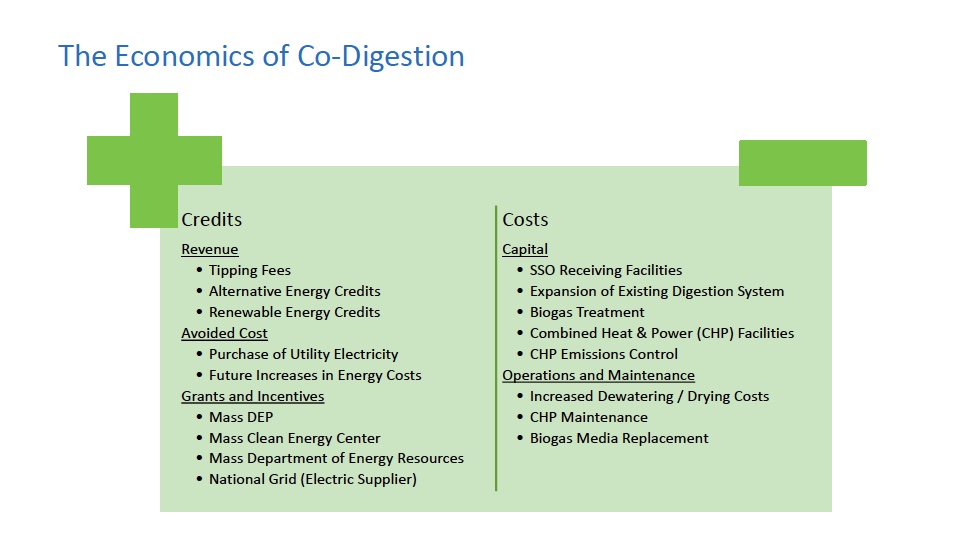

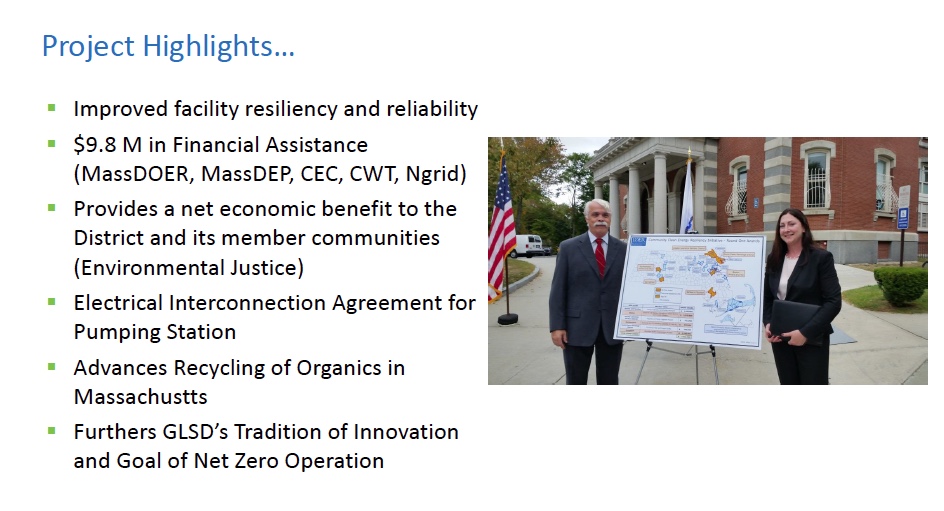

By 2020, GLSD may take in more than 90,000 gallons of food scraps per day and generate all the electricity it needs for the entire wastewater treatment process! This will take care of 40% Massachusetts’ food scrap diversion goal, making GLSD the state’s leader in food scrap management by anaerobic digestion. Because of this, the state has provided GLSD $10 million in incentive grants for this sustainability initiative.

More details